In the face of rising costs and labor shortages, digital twins are emerging as a game-changer in the competitive earthmoving sector, helping contractors safeguard their profit margins. But what exactly are digital twins? And how do they contribute?

What is a digital twin?

At their core, digital twins are virtual replicas of physical objects or sites. They’ve become essential across various industries as they allow for testing and adjustments before physical changes are made to a project.

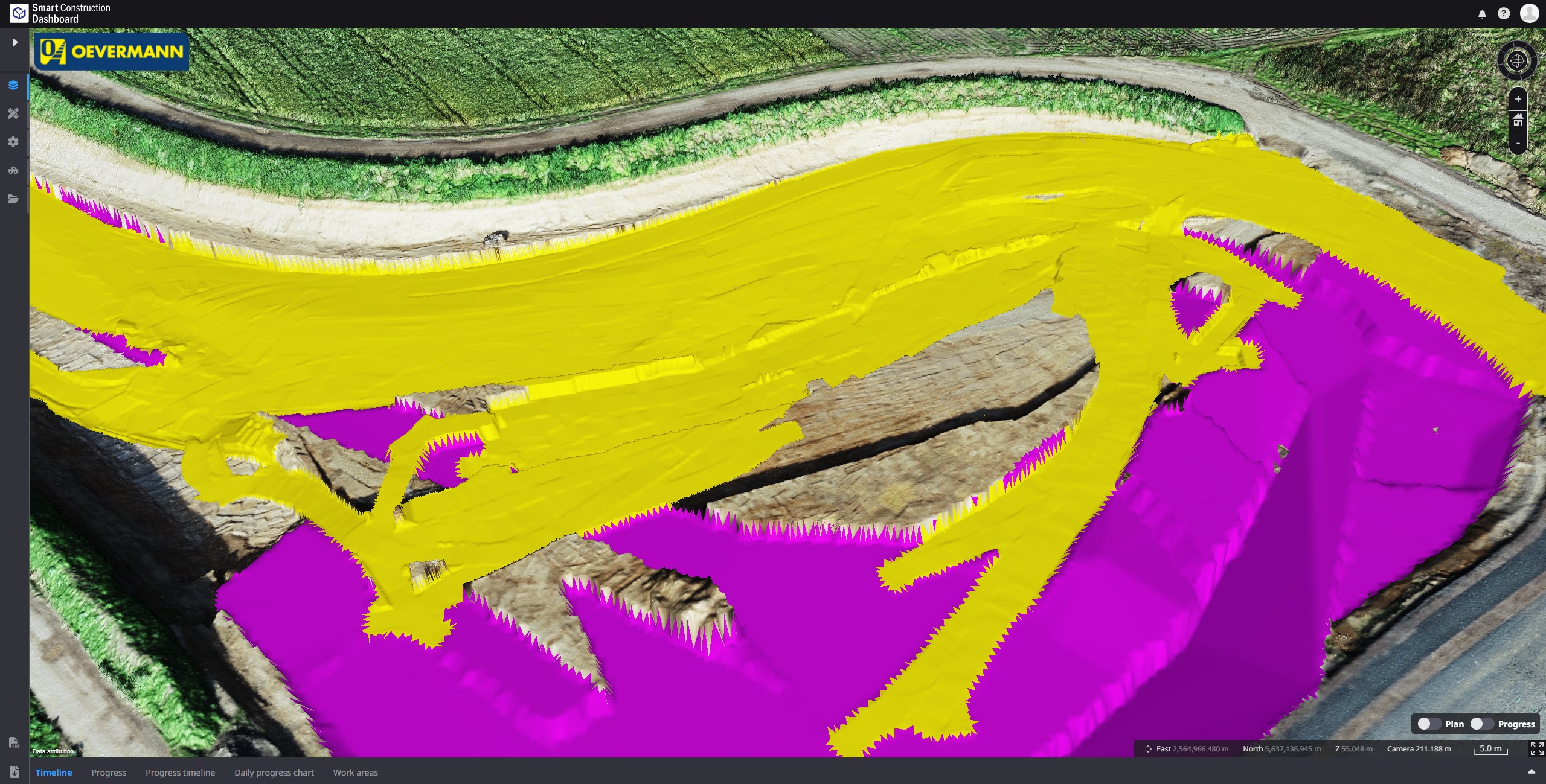

In the context of heavy civil earthmoving projects, a digital twin is an accurate, detailed virtual model of a physical jobsite. Updated continually through connected devices and sensors like 3D systems, intelligent machines, drones, and LiDAR, digital twins can be analysed and adjusted at all stages of the construction process. This capability helps identify optimisation opportunities from the bidding phase through to construction.

How do digital twins benefit the construction industry?

One of the significant challenges faced in earthmoving tasks is the unpredictability of what lies beneath the surface. Despite careful planning, unexpected conditions often emerge once digging commences, disrupting original plans. Here’s where digital twins come into play.

By monitoring site activities, assessing deviations, and modifying plans dynamically, digital twins ensure continual alignment with the project requirements. This adaptability allows for proactive decision-making on-site, from altering priorities and repositioning equipment, to introducing additional machinery or adjusting resources.

Unlike other digital solutions that reactively troubleshoot issues, digital twins can be proactively utilised during the planning stage. This proactive approach will ensure that projects are executed with confidence, knowing that the plans are well-informed and feasible. See how digital twin has saved Thomas Vent, site manager from ECOSOIL Nordwest GmbH, two working days per month.

How to build a digital twin?

To create a digital twin, data about the physical environment it represents is required. Every medium that captures the latest stage of the terrain, including drone surveys, intelligent machines, and 3D systems, can feed data to the digital twin.

As a project progresses, new data is continuously added to the digital model. This allows jobsite managers to easily understand daily progress in terms of volume.

When combined with simulations, a digital twin can visualise a project before it starts. By layering the design file on the initial terrain, digital rehearsals can be conducted in a virtual space. Here, different combinations of equipment and soil distributions can be tested before actual on-site implementation.

During the actual construction phase, the digital twin can help you make sure execution stays true to plan by keeping an eye on any deviation so that recovery action can be taken rapidly if needed.