That’s already some satisfying results, but our customer ECOSOIL Nord West GmbH – just like us – is dreaming big. On one of their recent jobsites Lager Waldteich, the site manager Thomas Vent was looking for an optimal way to track his team’s day-to-day productivity. In this article, we’d like to share with you how ECOSOIL has been harnessing daily as-built data directly from their intelligent machines, thanks to Smart Construction Dashboard.

ECOSOIL Nord West GmbH – One-stop service provider for land rehabilitation: “Wir machen Boden gut”

As one of the leading full-service providers for land rehabilitation in Germany, ECOSOIL Nord West GmbH (ECOSOIL) is backed by its solid reputation in earthwork and its ecological commitment. With around 300 employees, ECOSOIL demonstrates extensive experience and great expertise in land rehabilitation, environment-friendly earthworks, dyke construction, as well as landfill construction and operation. This is thanks to this expertise that ECOSOIL received in 2021 the Brownfield24 Award as the best ecological project for their land redemption in the old cocking plant Graf Bismarck in Gelsenkirchen.

Oberhausen – Lager Waldteich: Intelligent machine as-builts for daily jobsite status updates

On the jobsite of Lager Waldteich, the goal of ECOSOIL is to create a retaining structure on the former Waldteich coal storage site in which contaminated soil can be deposited. The jobsite manager Thomas Vent wished to closely monitor the volumes moved each day, so that he could make sure that the new material would be ordered and delivered in time. Having analyzed the situation, our advisory experts recommended ECOSOIL to make use of intelligent machine as-built data.

While Komatsu’s intelligent Machine Control (iMC) technology is famous for its advanced automation, a hidden trick is that the machine’s factory-installed cab top GNSS antenna automatically maps locations and elevations while the machine is working. So basically, we can get as-built data coming from the actual machine movement and progress on the jobsite. An iMC dozer, for example, collects as-built data based on the tracks running on the ground, meaning that it’s at any time possible to get an accurate terrain measurement from the dozer. It’s even possible to use the dozer as a survey tool by driving around the site and collect the as-built surface during the drive-around.

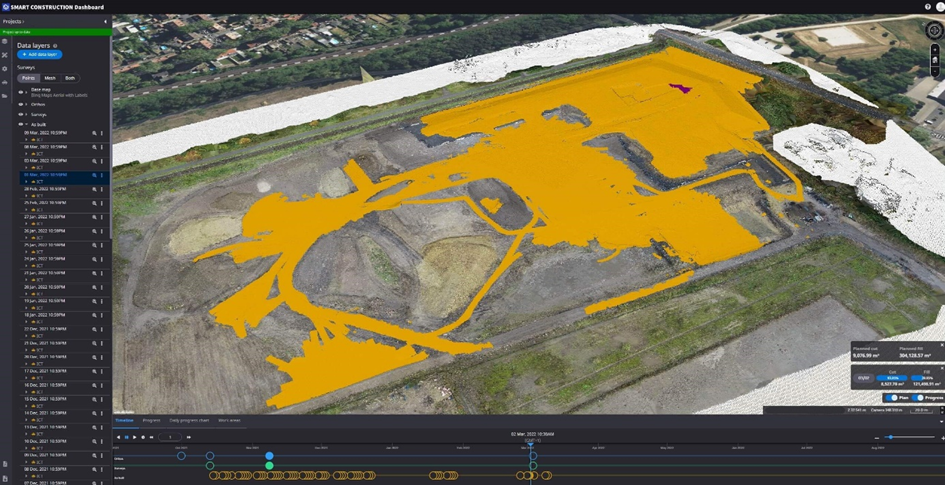

Thomas Vent decided to exploit the full potential of his intelligent machines. With the help of our advisory experts, his D61PXi and PC210LCi were connected to Smart Construction Dashboard – our web-based visualization tool that turns design, drone, machine and rover data into one 3D terrain map. Since day one, his intelligent machines have been sending as-builts to Dashboard, where they got automatically mapped over the initial terrain. On a daily basis, the jobsite manager could receive an updated jobsite status, and in a fully autonomous way, he could clearly visualize the job accomplished by his intelligent machines.

Thomas Vent: “Two working days saved per month”

For Thomas Vent, machine as-built data proved to be a valuable aid as they saved him a lot of time and hassle. “For the moment I’m managing two jobsites at the same time, and having my site status updates automatically every day on Smart Construction Dashboard is saving me a great deal of time,” said Mr. Vent, “with Komatsu intelligent machine as-built, you get survey data directly from your intelligent machines while they’re getting their job done. So if we do a quick calculation here, I think we have been able to save roughly 16 hours of traveling, surveying and data processing time per month, and this can be easily translated into two working days of supervising staffs.”

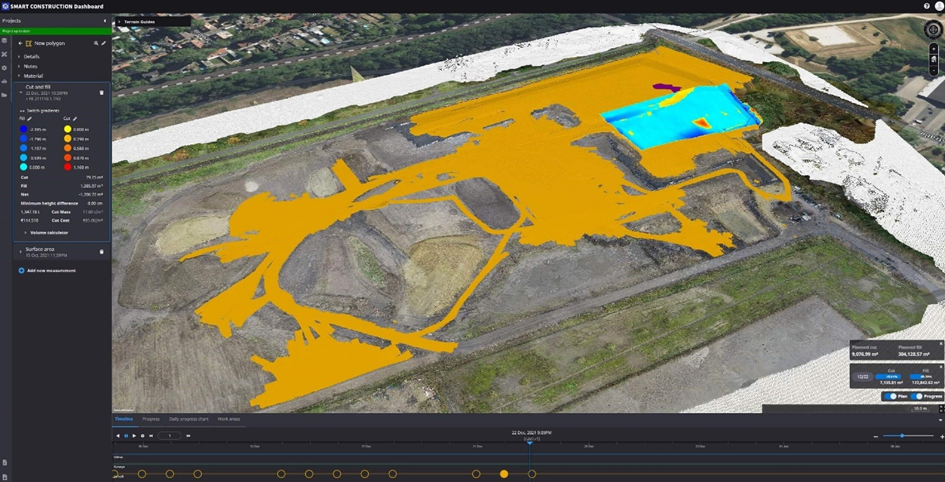

Saving time and money was not the only thing the jobsite manager achieved. With daily as-built data in hand, Mr. Vent could also understand the daily performance of his team in a way that was almost impossible before. In his own words: “I can figure out how much soil exactly is moved every day. So, if we are running behind or ahead of schedule on a particular day, I can notice it immediately and find out the reason. And when invoicing my client, I can always rely on Smart Construction Dashboard to back myself up with daily performance data.”

Mr. Vent was especially enthusiastic about the functionality enabling him to compare current progress with the final design: “The best part is that it’s just a matter of comparing the as-built with the design surface to know how many cubic meters were already moved or are left to move. Like this, I can well estimate when we’ll be finished. With better planning in mind, I can order new materials from my clients in a more proactive way, and no one in my team has to idle just because the deliveries hasn’t arrived yet.”

Integrated data for an optimal jobsite overview

The jobsite manager believed that it’s essential to have machine as-builts and drone data integrated at one place. As suggested by Smart Construction advisory experts, drone data offer a bird’s eye view with photorealistic details, and this provides important contextual information to machine movements. “It’s important for me to have initial terrain data, design data and all my survey data at one place. I see where my dozer goes and where my stockpiles are located. It helps me to make better decisions so that my team can work more effectively” said Thomas Vent. “What’s more, now I just need to open my web browser, log in to my account and I can access all my data. There’s no longer the need to open different software and do extra import or export”, Mr. Vent added.

More potential to be discovered

On jobsite Lager Waldteich, intelligent machine as-built proves to be a powerful tool to help the jobsite manager keep track of work progress on a daily basis. However, keep in mind that depending on the conditions of the jobsite and the purpose of the survey, you can do a lot more with daily as-built data. Get in contact with our advisory experts for a detailed analysis of your jobsite and make the best of your intelligent machines.